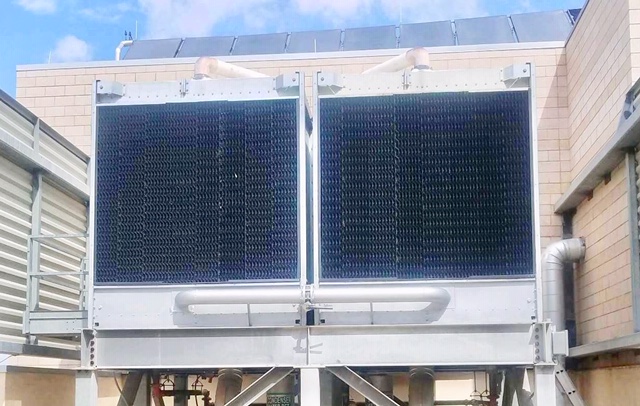

Freezing Weather Cooling Tower Maintenance

With the cooler months on the way the potential for freezing temperatures looms. While it isn’t very many days a year that Phoenix gets freezing temperatures it is important to know how to cope with it. This guide helps understand freezing weather cooling tower maintenance. Particular attention should be given to counterflow towers because it takes unique procedures to cut down the ice formation when it is running in below freezing temperatures.

Basics Of Freezing Conditions

The first and most important step is to understand each cooling tower’s needs in a given location and under various levels of use. The absolute best method is frequent visual inspections to get a baseline for each of the different operating conditions. Then you can predict the procedures that work for your given circumstances and your cooling tower.

Preheating the water in the basin is the key to successful winter start up and should be done before the water is directed up and over the tower. The industrial heat load must be applied to the tower with all of the return water being bypassed into the basin. After the water has reached about 80°F you can then stop the bypass and run the water through the cooling tower itself. Then the quantity of fans and their speed can be used to regulate the temperature of the water in the basin. If the temperature is low enough the fans might well all be turned off to maintain the temperature of the water in the basin.

During these colder operating conditions the thermal draft upward can be sufficient flow to keep the fans off or even at very low speeds. This system may well become an alternative to cold weather operation given the colder operating conditions.

Controlling Ice Buildup

Ice buildup can add weight and damage the cooling tower, concrete, and the fill. Ice that builds up on the lateral supports and columns should not be manually broken off as it is possible to damage the structure. The best method to removing the ice in these conditions is to utilize the heat from the industrial process to melt the ice. Fans should be slowed or even turned off to clear the supports of ice.

Extreme Weather Procedures

For some parts of Arizona below zero conditions do occur. In this conditions the standard procedure is to operate each of the individual fans in reverse every two to three hours. The period of time they are ran in reverse should not exceed 20 minutes.

Deicing control systems should be simple and follow a logical progression of events. It should look something like the following: The primary deicing switch would switch a group of fans to start slowing down, come to a stop, and shift into reverse. Having the ability to control individual groups of fans gives the flexibility to run extra deicing procedures on areas that are more prone to icing from direct wind or snow drift. The fans deicing cycle should not run longer than 30 minutes to prevent ice forming on fan stacks, fan blades, or drift eliminators.

Cooling tower operators should keep log books that record all of the data needed to develop an effective deicing strategy for your cooling tower. This log should include weather conditions, how many pumps are operating, individual fan speeds, and number of fans operating.

Regular Cooling Tower Inspection & Maintenance

The key to knowing what your cooling tower’s condition is, and what steps to take to fix it relies completely on regular inspection, repair and maintenance. This not only helps keep your cooling tower energy efficient but it ensures that all of the parts are ready for more extreme changes in weather conditions and either hotter or colder weather conditions. Don’t let them fall into neglect and end up failing you when you have work to do. Get your cooling towers maintained, repaired, or refurbished by All Kote Inc.